Original Equipment Manufacturers (OEMs) enforce stringent PDR quality standards to maintain vehicle integrity and value after collisions, driven by complex car designs and safety considerations. These standards present challenges for vendors, requiring significant investments in training, equipment, and process optimization, but success yields competitive advantages and stronger OEM partnerships.

Original Equipment Manufacturers (OEMs) demand exceptional Physical Damage Repair (PDR) quality from vendors due to stringent industry regulations and consumer expectations. This article explores why OEMs set such high PDR quality standards, delving into key factors driving this demand. We analyze the impact of strict controls on vendors and their capacity to meet OEM requirements, highlighting the importance of adherence to these critical PDR quality standards in today’s competitive automotive landscape.

- Understanding OEM Requirements for PDR Quality

- Key Factors Driving Demand for High Standards

- The Impact of Strict PDR Quality Controls on Vendors

Understanding OEM Requirements for PDR Quality

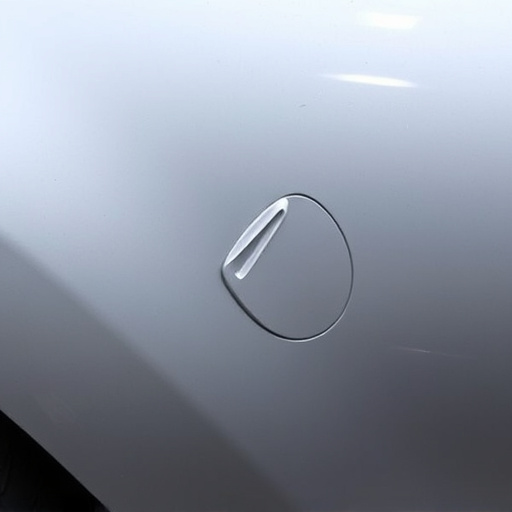

Original Equipment Manufacturers (OEMs) have stringent requirements when it comes to PDR quality standards, especially in the realms of collision damage repair and frame straightening. They demand precision and expertise to ensure vehicles are restored to their pre-accident condition, with minimal visible signs of previous repairs. This is not just about aesthetics; it’s also about safety. Proper PDR practices prevent structural weaknesses that could compromise a vehicle’s integrity during future accidents.

Vendors catering to OEMs must therefore adhere to rigorous quality control measures. This includes employing highly skilled technicians trained in the latest techniques for car scratch repair and other PDR services. Regular training, up-to-date equipment, and adherence to industry best practices are non-negotiable to meet these OEM demands. The ultimate goal is seamless integration of repair parts with the original vehicle design, ensuring both functionality and visual appeal.

Key Factors Driving Demand for High Standards

In today’s competitive automotive industry, Original Equipment Manufacturers (OEMs) are placing a premium on Part Damage Repair (PDR) quality standards. This demand is driven by several key factors. Firstly, with the rise of advanced manufacturing processes and materials, cars have become increasingly complex and expensive to produce. As such, OEMs want to ensure that any repairs or replacements maintain the vehicle’s original integrity and value.

Secondly, as car collision repair and auto glass replacement services become more prevalent, the need for high-quality PDR is evident. Car bodywork services must not only address visible damages but also ensure structural safety and reliability. This is particularly crucial in light of modern designs that incorporate lightweight materials and advanced safety features. Therefore, OEMs are demanding that vendors meet stringent PDR quality standards to guarantee customer satisfaction and vehicle performance.

The Impact of Strict PDR Quality Controls on Vendors

Strict PDR (Paint Damage Repair) quality controls implemented by OEMs (Original Equipment Manufacturers) present both challenges and opportunities for vendors. While these rigorous standards ensure high-quality repairs, they also demand significant investment in training, equipment, and process optimization from automotive body shops and tire services. Vendors must stay current with the latest frame straightening techniques and PDR quality standards to meet OEM expectations.

The impact extends beyond financial implications; it influences operational efficiency and reputation management. Shops that excel in PDR, by adhering to stringent guidelines, gain a competitive edge and build stronger relationships with OEMs. Conversely, those who struggle may face limited business opportunities and damage their brand image. Thus, continuous improvement in PDR quality is crucial for vendors aiming to thrive in the competitive automotive industry.

OEMs’ strict demand for high PDR quality standards reflects a dynamic market where precision and reliability are paramount. By setting robust PDR quality controls, OEMs ensure that their products meet stringent performance criteria, ultimately enhancing customer satisfaction. This trend empowers vendors to innovate while maintaining rigorous standards, fostering a competitive environment that drives continuous improvement in the industry.