Mastering PDR quality standards is crucial for top-tier vehicle restoration and customer satisfaction in today's automotive industry. Technological advancements like 3D scanning, advanced sensors, and software have revolutionized collision damage repair (PDR), focusing on accurate measurements, adherence to manufacturer specs, seamless finishes, and reduced repair times/costs. These innovations enable auto collision centers to provide enhanced services, ensuring vehicles are restored with improved safety features and aesthetic appeal reflecting the latest restoration innovations.

In today’s digital landscape, ensuring precise and reliable Patient-Centered Medical Home (PCMH) data is paramount. This article explores the pivotal role technology plays in verifying PDR quality standards. We delve into the current state of PDR quality metrics, analyze how technological advancements streamline verification processes, and showcase innovative tools enhancing quality assurance. By embracing these technologies, healthcare providers can navigate the intricate web of PDR quality standards with greater efficiency and accuracy.

- Understanding PDR Quality Standards Today

- Technology's Impact on Verification Processes

- Streamlining Quality Assurance with Innovative Tools

Understanding PDR Quality Standards Today

In today’s automotive industry, understanding PDR quality standards is paramount to ensuring optimal vehicle restoration and customer satisfaction. PDR, or collision damage repair, involves meticulously repairing and restoring car bodywork to its pre-incident condition. These quality standards have evolved significantly, driven by advancements in technology and an increased focus on precision and safety. Key metrics include the accuracy of measurements, adherence to manufacturer specifications, and achieving seamless finishes that match the vehicle’s original paint job—all while minimizing repair times and costs.

Modern tools like advanced sensors, 3D scanning technologies, and sophisticated software platforms play a crucial role in meeting these standards. They enable technicians to accurately assess and document collision damage, facilitating precise repairs and restoration of car bodywork. This not only enhances the overall quality of PDR services but also ensures that vehicles return to the road with enhanced safety features and aesthetic appeal, reflecting the latest advancements in the field of car restoration.

Technology's Impact on Verification Processes

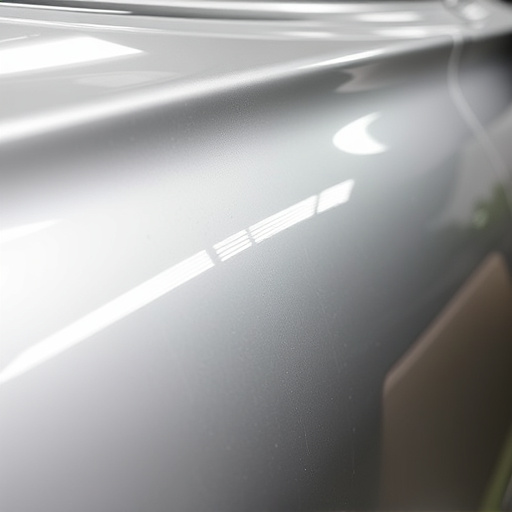

The advent of technology has significantly transformed verification processes in the field of PDR (Panel Replacement and Repair) quality standards. Modern tools like digital measurement systems, advanced imaging technologies, and specialized software enable more precise assessments compared to traditional manual methods. These innovations ensure that each collision repair service or auto collision center adheres to stringent quality guidelines, minimizing errors and maximizing customer satisfaction.

Additionally, technology facilitates faster and more efficient verification by streamlining documentation processes, automating data entry, and providing real-time feedback. This not only reduces the risk of human error but also allows professionals in car collision repair centers to focus on intricate details that were previously challenging to capture accurately. As a result, the overall quality of collision repair services is enhanced, ensuring vehicles return to their pre-accident condition.

Streamlining Quality Assurance with Innovative Tools

The automotive industry’s evolution has brought about a heightened focus on maintaining optimal PDR quality standards, especially with the intricate nature of modern vehicles. Traditional methods of quality assurance in car collision repair and luxury vehicle repair often consumed significant time and resources, hindering efficiency. However, technological advancements have introduced innovative tools that streamline this process, revolutionizing how professionals approach PDR quality.

These cutting-edge solutions enable precise measurements, detailed imaging, and efficient data analysis, ensuring every aspect of tire services and repairs meets the required standards. By automating various tasks, these technologies reduce human error, enhance productivity, and ultimately contribute to better outcomes. As a result, technicians can focus on more complex tasks, ensuring that every repair, regardless of its scope—from minor dents to major structural damage—meets the highest quality benchmarks.

Today, the integration of technology has significantly revolutionized the way PDR (Patient-Driven Reporting) quality standards are verified. By leveraging innovative tools and digital solutions, healthcare professionals can streamline quality assurance processes, ensuring accurate and efficient reporting. This shift not only enhances overall data integrity but also allows for more effective navigation of evolving PDR quality standards in today’s dynamic healthcare landscape.