The PDR (Paintless Dent Repair) quality standards are comprehensive guidelines designed to elevate vehicle collision repair and dent removal processes. By demystifying criteria that include pre- and post-repair inspections, advanced tools, precision, efficiency, and minimal disruption to finishes, these standards empower technicians and shops alike. Integrating these standards into daily operations through rigorous training, equipment calibration, and quality control results in superior customer satisfaction and increased trust. Regular tracking of key performance metrics, data-driven initiatives, and updates to the PDR quality standards ensure Mercedes-Benz repair services maintain industry best practices and consistently deliver top-notch repairs.

“In an era where precision and consistency are paramount, the integration of PDR (Paintless Dent Repair) quality standards is a game-changer for the automotive industry. This article explores the comprehensive guide to implementing these standards, offering a step-by-step approach to enhance service quality. From understanding the fundamentals of PDR quality standards to measuring their impact, we delve into strategies that ensure consistent excellence. Discover how this integration can revolutionize your operations and set new benchmarks in customer satisfaction.”

- Understanding PDR Quality Standards: A Comprehensive Overview

- Integrating Quality Standards into Daily Operations

- Measuring Success and Continuous Improvement Strategies

Understanding PDR Quality Standards: A Comprehensive Overview

The PDR (Paintless Dent Repair) quality standards are a set of guidelines designed to ensure excellence in the field of vehicle repair, specifically focusing on auto collision repair and dent removal. This comprehensive overview aims to demystify these standards for both seasoned professionals and those new to the industry. By understanding these criteria, collision repair centers can enhance their practices, resulting in superior customer satisfaction and increased trust in their services.

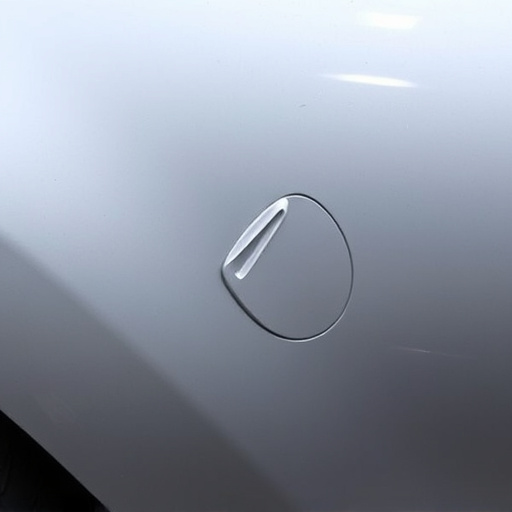

PDR quality standards cover various aspects of vehicle repair, from pre-and post-repair inspections to the use of advanced tools and techniques. It emphasizes precision, efficiency, and minimal disruption to the original finish. The standards promote a systematic approach to dent removal, ensuring each step is documented and performed with the utmost care. This includes training requirements for technicians, equipment calibration, and quality control measures, all of which contribute to maintaining high-quality auto collision repair standards.

Integrating Quality Standards into Daily Operations

Integrating PDR quality standards into daily operations is a transformative process that requires a strategic approach. It involves aligning everyday tasks with the stringent requirements set forth by PDR, ensuring every automotive repair, car paint repair, and vehicle paint repair meets the highest industry benchmarks. This means training staff to recognize and adhere to these standards, from pre-repair assessments to post-completion quality checks. By seamlessly weaving these practices into existing workflows, shops can elevate their service offerings, fostering customer satisfaction and loyalty.

This integration goes beyond mere compliance; it empowers technicians to deliver consistent, top-tier results. Standardized procedures for car paint repair, for instance, ensure that every scratch or dent is accurately assessed and treated uniformly, minimizing variations in the final finish. Similarly, implementing standardized automotive repair protocols across the board can lead to faster turnaround times and reduced errors, ultimately enhancing operational efficiency and customer experience.

Measuring Success and Continuous Improvement Strategies

Measuring success and implementing continuous improvement strategies are vital components of seamlessly integrating PDR quality standards into vehicle repair services, such as those offered by Mercedes-Benz repair shops. The key to gauging progress lies in establishing clear performance metrics that align with the adopted PDR standards. These could include factors like customer satisfaction ratings, repair accuracy rates, and turnaround times. By regularly tracking and analyzing these metrics, auto repair shops can identify areas where they excel and pinpoint specific aspects needing refinement.

Continuous improvement initiatives should be data-driven and focused on enhancing overall quality. This involves fostering a culture of learning within the shop, encouraging team members to suggest improvements, and adopting innovative techniques or technologies that align with PDR standards. For instance, implementing digital documentation systems can streamline processes, improve accuracy, and facilitate efficient knowledge sharing across the entire Mercedes-Benz repair team. Regular reviews and updates to quality standards will ensure the auto repair shop remains at the forefront of industry best practices, providing top-notch vehicle repair services.

As we’ve explored, integrating PDR quality standards into daily operations represents a significant step forward for any business aiming to enhance service excellence. By understanding these standards, strategically implementing them, and continuously measuring success, organizations can ensure they’re providing the highest level of care. Embrace this process as an ongoing journey, leveraging data-driven insights to refine and optimize your practices over time. This commitment to quality will not only drive customer satisfaction but also position your business as a leader in the industry, setting a new standard for excellence.