The PDR (Paintless Dent Repair) quality standards are comprehensive guidelines for auto collision repair technicians, focusing on equipment proficiency, technician training, best practices, and customer satisfaction. These standards ensure that repairs preserve vehicle aesthetics, achieve precise color matching, and maintain panel alignment, enhancing safety and customer satisfaction. Adhering to these guidelines requires a systematic approach involving meticulous measurements, up-to-date tools, quality control processes, and specialized training for technicians, ultimately ensuring restored vehicles meet or exceed industry and customer expectations.

In today’s auto repair landscape, meeting Paint Damage Repair (PDR) quality standards is paramount for technicians. This article guides you through the essential components of achieving excellence in PDR, from understanding the defining criteria to mastering the technician’s role and implementing consistent improvement strategies. Discover key practices, tools, and techniques that ensure every repair meets or exceeds industry expectations, enhancing customer satisfaction and fostering a reputation for quality craftsmanship.

- Understanding PDR Quality Standards

- – Definition and significance of PDR (Paint Damage Repair) standards

- – Key components and criteria for meeting quality expectations

Understanding PDR Quality Standards

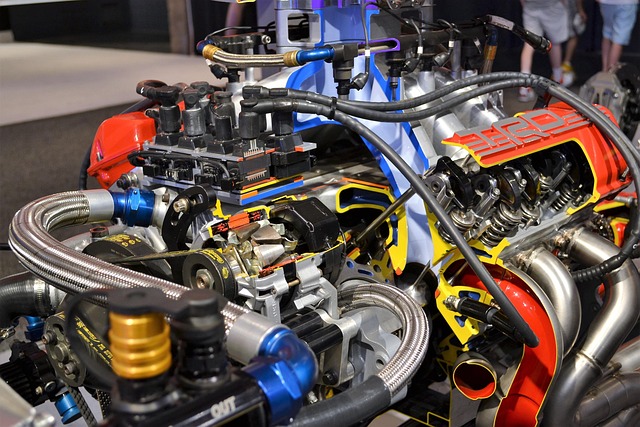

The Professional Dent Repair (PDR) quality standards are a set of rigorous guidelines designed to ensure that auto dent repair and vehicle collision repair services maintain exceptional quality. These standards focus on several key areas, including equipment proficiency, technician training, adherence to industry best practices, and customer satisfaction. Technicians aiming to meet these benchmarks must possess expertise in various techniques such as paintless dent repair, which involves meticulous precision without disturbing the original finish, a skill crucial for preserving the vehicle’s aesthetic value.

Understanding PDR quality standards is paramount for technicians in the auto detailing sector. It encompasses not just repairing dents but also ensuring color matching accuracy, proper panel alignment, and seamless restoration of the vehicle’s pre-collision condition. By adhering to these standards, technicians contribute to the overall safety and satisfaction of customers who rely on them to restore their vehicles to their best post-accident state, be it an auto dent repair or a more extensive vehicle collision repair.

– Definition and significance of PDR (Paint Damage Repair) standards

The Paint Damage Repair (PDR) standards are a set of critical quality measures designed to ensure that car paint repair and bodywork restoration services meet or exceed industry expectations. These standards are pivotal in maintaining the aesthetics and long-term value of vehicles, especially post collision repairs. PDR quality standards cover various aspects, from the selection of compatible paints and proper application techniques to ensuring color match precision and achieving a seamless finish.

Adherence to these guidelines is essential for technicians in the car collision repair sector. It guarantees that customers receive high-quality, professional work on their vehicles, restoring them to their pre-accident condition. By adhering to PDR quality standards, technicians can confidently deliver top-notch car paint repair services, fostering customer satisfaction and maintaining a competitive edge in the market.

– Key components and criteria for meeting quality expectations

Meeting PDR quality standards in a vehicle body shop is no easy feat but it’s achievable through a keen focus on several key components. These include precise measurements, meticulous panel alignment, and adherence to strict industry guidelines for auto frame repair and auto body restoration. Technicians must be equipped with the latest tools and training to ensure they can deliver consistent, high-quality results that meet or exceed customer expectations.

Furthermore, a systematic approach to quality control throughout each stage of the repair process is crucial. This involves thorough inspections, using specialized equipment for auto body restoration, and implementing best practices for panel replacement and painting. By focusing on these aspects, technicians can ensure that every vehicle leaving their shop is not just fixed but restored to its pre-accident condition, reflecting the highest standards in the industry.

Technicians can effectively meet PDR quality standards by understanding and adhering to the key components outlined in this article. By mastering techniques, staying updated with industry best practices, and consistently evaluating repairs against defined criteria, technicians can ensure their work not only meets but exceeds PDR quality expectations. This commitment to excellence fosters customer satisfaction and maintains the reputation of the repair shop as a reliable, high-quality service provider.