PDR quality standards ensure excellence in auto body repair by focusing on meticulous painting and surface restoration. Adhering to these standards involves specific procedures for preparation, application, and inspection using clean tools and materials. Compliance guarantees high-quality repairs, restoring vehicles to like-new conditions. Setting benchmarks, inspired by industry best practices, and maintaining consistent quality through standardized procedures ensure flawless results, building client trust for Mercedes-Benz collision repair services.

“Uncover the essentials of PDR quality standards with our comprehensive beginner’s guide. Learn how to navigate the fundamentals, set benchmarks for exceptional paint restoration, and implement consistent quality results. From defining key terms to practical tips for maintenance, this guide equips you with the knowledge needed to excel in PDR. Master the art of restoring vehicles to their pristine condition using proven PDR quality standards.”

- Understanding PDR Quality Standards: Basics Unveiled

- Setting Benchmarks for Excellence in Paint Restoration

- Implementing and Maintaining Consistent Quality Results

Understanding PDR Quality Standards: Basics Unveiled

PDR quality standards are a set of guidelines designed to ensure excellence and consistency in auto body repair and restoration processes. These standards focus on the art of painting and repairing damaged vehicle surfaces, aiming to bring them back to their original condition or even enhance their appearance. Understanding PDR quality standards is crucial for anyone involved in the auto maintenance industry, especially car body shops offering auto repair services.

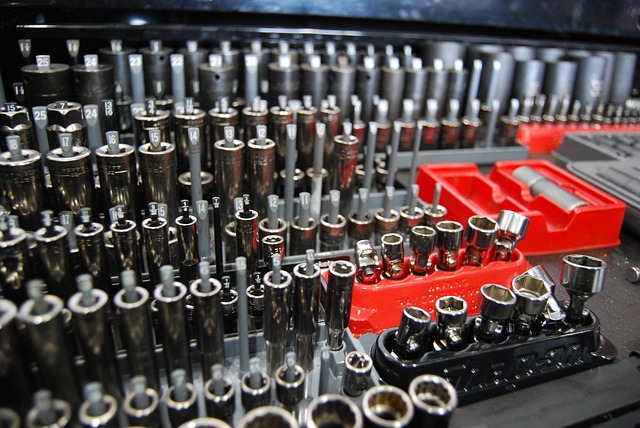

The basics involve adhering to meticulous procedures that cover everything from surface preparation to paint application and final inspection. These include using appropriate tools and materials, following specific techniques, and maintaining a clean, controlled environment to prevent contamination. By adhering to these standards, car body shops ensure their work meets high-quality criteria, providing customers with top-notch auto repair services and restoring their vehicles to like-new condition.

Setting Benchmarks for Excellence in Paint Restoration

Setting benchmarks for excellence in paint restoration is a cornerstone of achieving top-tier PDR quality standards. It involves establishing clear and measurable goals that guide technicians in their pursuit of flawless results. These benchmarks cover various aspects, from ensuring precise color matching to perfecting the finish’s smooth texture. By setting such standards, professionals in automotive body work, like those handling Mercedes-Benz collision repair, can ensure every dent removal process meets or exceeds customer expectations.

Understanding industry best practices and drawing inspiration from renowned paint restoration experts are essential steps in this journey. Technicians should regularly assess their work against these benchmarks, using advanced tools and techniques to refine their skills continuously. This commitment to quality not only enhances the overall aesthetic of car dent removal but also builds trust among clients seeking top-notch Mercedes-Benz collision repair services.

Implementing and Maintaining Consistent Quality Results

Implementing and maintaining consistent quality results is a cornerstone of achieving PDR quality standards in autobody repairs. This involves meticulous attention to detail at every stage of the restoration process. For instance, ensuring proper surface preparation prior to painting is vital; this includes thorough cleaning, sanding, and priming to create an even base for subsequent coats. Standardized procedures and training ensure that these steps are executed uniformly across different work stations, minimizing variations in quality.

Regular quality control checks play a pivotal role in maintaining consistency. This involves inspecting completed autobody work against set benchmarks and PDR quality standards. Using advanced tools like moisture meters for paint inspection or color matching systems to verify pigment accuracy can significantly enhance precision. By fostering a culture of continuous improvement and adherence to these standards, repair facilities can deliver high-quality hail damage repairs that meet customer expectations and industry benchmarks.

PDR quality standards are not just guidelines; they’re a roadmap to exceptional paint restoration. By understanding the basics, setting clear benchmarks, and implementing consistent practices, you can achieve top-notch results that meet or exceed industry expectations. Remember, maintaining high PDR quality standards is an ongoing process, requiring regular evaluation and adjustment. Embrace these principles, and you’ll be well on your way to becoming a master in the art of paint restoration.